Art and science

Sharing techniques behind creating gold hoops and a cathedral engagement ring

Making jewelry is equal parts art and science. You have to consider design, construction, and process to create a successful piece. I find all elements fascinating, but I think the scientific side (construction and process) are generally opaque for consumers. Therefore, I’m going to share more details about how I make my pieces.

I spent a few hours this week carefully polishing two pairs of 18 karat gold Sunbeam Hoops. Their many grooves and surfaces increase the challenge of bringing out the gold’s full radiance. I used a magnifier to inspect each hoop as I worked.

Now that the hoops are polished, the next step is to solder the earring posts to them.

Although it takes more time, you often want to polish a piece’s components separately before joining them together. For these hoops, accessing the interior becomes difficult once the post is attached. The polishing buffs can get caught and easily bend the post or snag and scratch the gold, which is very time-consuming to correct and a waste of costly material.

Because I already brought the hoops to a high-polish, after I solder the posts they will just require a quick clean-up and final polish. Super excited to show the finished pieces next week!

New cathedral ring

I began a new sterling silver ring featuring a rhodolite garnet. The goal is to make a classic engagement-ring style ring with a cathedral setting. A cathedral setting gets its name from the structural elements that resemble the arches in doorways and ceilings of Gothic-style cathedrals; the stone is raised above the ring and flanked by arches of metal rising from the shank.

A cathedral setting is one of the most popular styles for engagement rings and creates a strong, architectural profile.

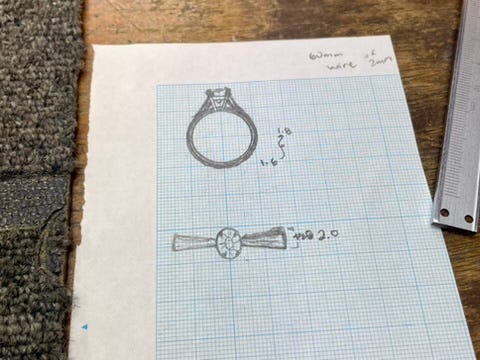

I started the process with a simple sketch of the rough design. I drew the ring from the side and top views to better visualize its construction. Making jewelry is often like working a puzzle backwards.

While a lot of everyday fine jewelry tends to be dainty, engagement rings - especially very high-end ones - are usually more substantial. A thin band (I would say <1.5mm) is too fragile for regular heavy wear and risks bending or breaking, especially with a large stone.

For this new ring, I want the band to be 2mm wide and taper toward the center stone. 2-3mm is a typical band width for engagement rings and balances durability with elegance.

I created the shape of the band from a 2mm silver square wire. I used a rolling machine to slightly flatten one direction of the wire (this slightly thinner direction will be the height of the band; the thicker direction will be the 2mm width). After annealing the metal (heating it up then quenching it in water), I used a hammer and rounded pliers to shape the band and the arched cathedral.

Next, I rolled out a small length of the same 2mm square wire to about 1.5mm for the inner curve of the band. There is no set rule about the thickness ratio of this inner piece, but the profile looks more elegant if it is thinner than the main band. Slowly, I started shaping it to fit between the arches. Next week I will solder the pieces together.