February 2 this year is setsubun-no-hi (節分の日) in Japan - the day before the first day of spring according to the Japanese lunar calendar.

A tradition of the holiday is to throw roasted soybeans at an oni (demon). I have a traumatic vivid childhood memory of frantically throwing soybeans at my dad wearing an oni mask while screaming "Oni wa soto! Fuku wa uchi!" ("Devils out! Fortune in!").

Anyways, a few weeks ago when I was at my parents’ house hunched over carving wax for hours, my mom jokingly called me “Oni!”. In this context, it meant something akin to “possessed!”.

Possessed

You have to be obsessed - almost possessed - if you want to handcraft your jewelry pieces professionally.

The amount of time, effort, and money required to develop your skills and knowledge enough to bring designs to life is enormous.

What I’ve realized through jewelry and other life/business experiences over the past few years is that it’s easier than you’d expect to start something and do a subpar or average version of it.

It’s much more difficult than you’d expect to do an excellent version of something.

The oft-repeated 80-20 principle in business resonates: 80% of all outcomes are derived from 20% of causes. And you really need to be possessed to find success in that 20%.

New Skills

This past week included soldering for the first time, an improvement in my wire wrapping, and lots of sanding/polishing practice.

Soldering is the process of joining two pieces of metal together through an intermediary material (the solder). Using the gas torch at school, I heated up the solder to fuse the two ends of the ring. I bought a small butane torch over the weekend so that I can practice at home. Soldering is critical for connecting pieces together, such as the backing of an earring to its body.

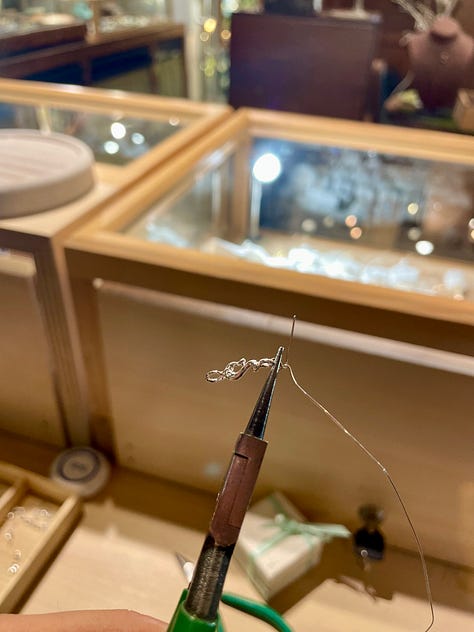

The first jewelry-making technique I learned at ileava jewelry was wire-wrapping. Wire-wrapping is very useful as it allows you to connect pieces together without solder or heat. It took me around 2 months of semi-regular practice to significantly improve. My initial attempts were uneven and brittle, but my mentor, Maya, said that I improved enough that next week I can try wire-wrapping a bracelet for her to put on the shop floor!

Sanding and polishing remain a pain in the ass an area for growth. It is incredibly time-consuming and a bit physically demanding to sand and polish each piece. I still struggle to independently achieve the mirrored finish that my flat ring from school has. Hopefully I will soon learn more techniques to make sanding and polishing better.

Planning

I am realizing how much planning is required to successfully run a jewelry business. Even as a hobby, making a single piece necessitates advanced thought.

You have to design and make the piece, cast it (if using the lost wax method), refine it, get molds made if needed, solder or set stones as required, and polish it. Depending on the piece, this process may take weeks or months.

As I am learning through my apprenticeship and jewelry school, getting a piece to commercial perfection requires meticulous measurement and many steps to refine.

I am trying to take a more conscientious approach to creating new pieces. I’m thinking about designs that I would not only wear, but buy if someone else had made them.

So that means working my way toward creating in gold, incorporating pearls, and considering how a piece can be styled within a wardrobe.

At least, that’s the plan! :)